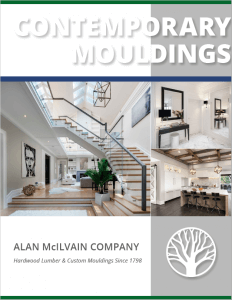

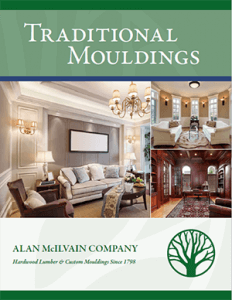

Standard and Custom Mouldings

With more than 50,000 knives in stock and the ability to custom manufacture virtually any profile, Alan McIlvain is your one stop shop for high end solid hardwood mouldings. Utilizing our extensive lumber inventory, five high-speed Weinig moulders and some of the most skilled operators in the industry, we consistently produce superior quality mouldings with short turnaround times.

In addition to milling and custom CNC knife-grinding, our full service capabilities include priming and buffing. Our Cefla vacuum coater and infrared curing oven apply a thin coat of primer that cures instantly to seal the wood, eliminating the costly and time consuming process of priming and sanding in your shop or at a job site.

You can rely on us as your go-to hardwood moulding manufacturer. Phone, fax or email one of our experienced sales representatives to see what Alan McIlvain can do for you.

Moulding Catalogs

Download our 2020 catalog CAD File

Browse all Moulding Profiles by type

Please select a millwork profile:

Architectural Woodworking Institute is an excellent source for information, education and specifications on types of mouldings and profiles.

Overview of Millwork Operations at Alan McIlvain Company

Custom CNC Knife Grinding

Our state of the art Weinig CNC knife grinder can sharpen and grind tooling to a precision that simply cannot be achieved through the traditional method of grinding by hand. Custom profile CAD drawings can now be transformed into high speed steel tooling with amazing speed and quality.

Primed and Buffed Mouldings

Starting with high quality mouldings, our new Cefla vacuum coater and IR oven high-speed priming line allow us to provide the primed mouldings for your every project using latex based primer. This provides you with a primed and buffed moulding surface that’s ready to be painted.